From the Customer’s Idea or Product Profile, we take the project through a total tooling life cycle.

CQI

Our comprehensive die design model is ever evolving. We ensure that every design is improved for each subsequent model. Each profile is assessed before tool design begins.

CUSTOMER CONCEPT

Please send us an extruded product for assessment or ask for comment on a die design that is not producing profitably.

- Supplies Section Drawing or profile for assessment.

- Profile Assessment creates strategies for reliable supply of extruded product and profile design developments.

- Begins with initial discussion on product needs and Customer expectation.

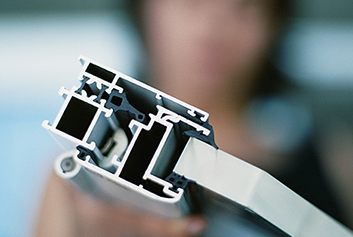

PROFILE ASSESSMENT

Section assessment is an important step to realising profitable extrusion. Productive customer communication can set the foundation for reliable supply.

- Important to identify product use prior to die design.

- Identify critical dimensions.

- Examine entire application of product and apply suitable tolerances.

- Discuss improvements for both extrudeability and fabrication gains.

- Identify process constraints such as extrusion pressure, cooling, product evacuation and packing.

- Invite comment from colleagues to expand all ideas.

- Allow Customer to examine all of this research.

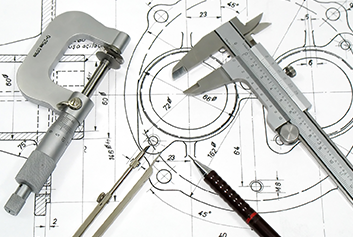

TOOL DESIGN

A team effort is needed to maintain our standards. All designs are conceived using a group rather than solo effort.

- Involve Die Maker in the early stages to assess manufacturing process.

- Open discussion with other Die Makers if necessary.

- Discuss and identify important elements associated with each individual design.

- Complete the design and open discussion with design team, die shop manager and extrusion staff.

- Offer feedback to the Die Maker to assist in development of all stages of design.

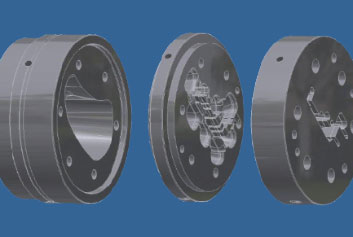

TOOL MANUFACTURE

All design work offers a complete and transparent communication with the Customer.

- Involve Die Maker in the early stages to assess manufacturing process.

- Open discussion with other Die Makers if necessary.

- Discuss and identify important elements associated with each individual design.

- Examine improvements at every stage.

- Offer feedback to the Die Maker to assist in development of all stages of design.

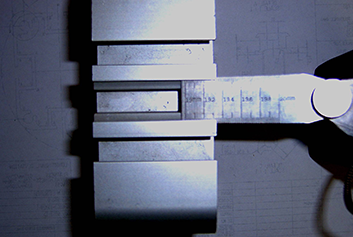

TOOL PREPARATION & MAINTENANCE

CQI methods of Tool Preparation and maintenance differ from most Extrusion Plants. Our Die Shops require less staff.

- Every design includes maintenance and tool preparation advice.

- With more complex designs advice on trial and sample inspection is also supplied.

- The Design Team is always available for consultation and feedback for continuous improvement.[/wr_item_tab][wr_item_tab heading=”7.

Long-Term Die” disabled_el=”no” ]

LONG-TERM DIE MAINTENANCE

Consultation on steel, heat treatment and standard of tool maintenance is assessed with each new customer

- Nitriding depth and frequency measured in meters included with each design.

- Advice on minimizing maintenance time.

- Feedback and consultation available for each design.

PRODUCTION

It is necessary that Extrusion Optimisation is assessed by observing every extrusion condition.

- Each extrusion press or plant is different. There are rarely identical extrusion conditions.

- Each die is designed with the constraints and strengths of each individual plant considered.

- All recommended process parameters such as die temperature, billet temperatures, expected extrusion speeds are included.

- Observations that may be necessary such as cooling, exit temperature ageing etc. are also discussed.

- Optimum billet length and extrusion speed will always be pursued as the primary option.

PROCESS CONTROL

To reach optimisation Process Control must be observed and maintained.

- Development discussions on process control are generally held during Profile Assessment.

- Every Plant is different so assessment pre-design is always important.

This includes alloy and temper, reduction ratio, extrusion temperatures and ageing to name a few.

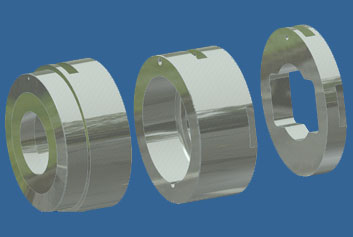

SUPPORT TOOLING

CQI has advanced designs for Support Tooling. We welcome your enquiry.

- Die Rings/Holders, Bolsters, Inserts and Spreaders are under constant development at CQI.

- CQI has a proven development programme for extruding profiles with lowcross-sectional area (high reduction ratio) using a specially designed Die Rings.

- This is a process unique to CQI. This helps increase the variability of profiles that can be extruded on any single Press.

- CQI also has a proven design record for extruding profiles larger than the Container.

INDEPENDENT CONSULTATION & ADVICE

- Review design performance and improvement to die designs not designed by CQI.

- Supply correction and maintenance advice to dies not designed by CQI.

- Offer Profile Assessment without progressing to die design.